Plastic Extrusion

-

Hot Extruding Steel

During hot extrusion a round steel billet is pre-heated and, after leaving the furnace, is pushed through a forming die into a profile bar using a ram with an extrusion force of 2,200 t. Hot extruding offers substantial advantages in comparison with hot rolling, forging or machining. Hot extrusio...Read more -

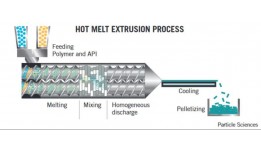

HME (Hot Melt Extrusion) Related Features

Rotation of the screws,There are two families of twin screw extruders,material selection is critical in the development of a successful product… Rotation of the screws creates distributive and dispersive mixing. Distributive mixing maximizes the division and recombination of the mater...Read more -

Horizontal PTFE Extruder

Horizontal PTFE extruder gives our customers great flexibility while occupying a minimum amount of floor space. Horizontal extruders are come in standard sizes of 25-Ton, 50-Ton, 75-Ton, and 100-Tons of thrust, with stroke lengths of 36″, 54″, 72″, 108″ and the World’s Lo...Read more -

Types of Plastic Extrusion Process

The plastic extrusion process is broadly classified into seven different types depending upon the specific applications. (a) Sheet/Film Extrusion In this extrusion process, the molten plastic material is extruded through a flat die. The cooling rolls are used to determine the thickness of sheet/f...Read more -

Types of Plastic Extrusion

There are variations to the extrusion process depending upon what type of extrusion is being performed. Here is a look at the different types of extrusion, and the differences from the basic process for each. Sheet Extrusion Sheet extrusion, also known as film extrusion, is used for making plasti...Read more -

Types of Hot Melt Extrusion

Hot-melt extrusion (HME) is an established process that has been used since the early 1930s, predominately in the plastics manufacturing … There are two types of extruders: single and twin screw extruders. Single screw extruders are primarily used for melting and conveying polymers to extru...Read more